-

Home

-

About Us

-

Products

- Butterfly Valve

- Triple Offset Butterfly Valve

- Double Eccentric Butterfly Valve

- Resilient Seated Butterfly Valve

- High Performance Butterfly Valve

- Ball Valve

- Threaded Ball Valve

- SW/BW Ball Valve

- Floating Ball Valv

- Trunnion Ball Valve

- Full Welded Ball Valve

- Gate Valve

- Forged Gate Valve

- Casting Steel Gate Valve

- Casting Iron Gate Valve

- Knife Gate Valve

- Globe Valve

- Forged Globe Valve

- Casting Steel Globe Valve

- Casting Iron Globe Valve

- Check Valve

- Forged Check Valve

- Lift Check Valve

- Swing Check Valve

- Disc Check Valve

- Butterfly Type Check Valve

- Silent Check Valve

- Rubber Disc Check Valve

- Hydraulic Control Valve

- Fixed Cone Valve

- Plunger Valve

- Hydraulic Valve

- Air Vent Valve

- Plug Valve

- Lubricated Plug Valve

- Non-lubricated Plug Valve

- Actuators

- Pneumatic Actuator

- Electrical Actuator

- Hydraulic Actuator

- Pipe Fitting

- Joints

- Flanges

- Strainer

-

Applications

- Industry

- Water and Wastwater

- Oil and Gas

- Chemical and Petrochemical

- Mining and Metal

- Food and Drinking

- Slurry and Paper

- Power

- Marines

-

Resources

-

Home

-

About Us

-

Products

- Butterfly Valve

- Triple Offset Butterfly Valve

- Double Eccentric Butterfly Valve

- Resilient Seated Butterfly Valve

- High Performance Butterfly Valve

- Ball Valve

- Threaded Ball Valve

- SW/BW Ball Valve

- Floating Ball Valv

- Trunnion Ball Valve

- Full Welded Ball Valve

- Gate Valve

- Forged Gate Valve

- Casting Steel Gate Valve

- Casting Iron Gate Valve

- Knife Gate Valve

- Globe Valve

- Forged Globe Valve

- Casting Steel Globe Valve

- Casting Iron Globe Valve

- Check Valve

- Forged Check Valve

- Lift Check Valve

- Swing Check Valve

- Disc Check Valve

- Butterfly Type Check Valve

- Silent Check Valve

- Rubber Disc Check Valve

- Hydraulic Control Valve

- Fixed Cone Valve

- Plunger Valve

- Hydraulic Valve

- Air Vent Valve

- Plug Valve

- Lubricated Plug Valve

- Non-lubricated Plug Valve

- Actuators

- Pneumatic Actuator

- Electrical Actuator

- Hydraulic Actuator

- Pipe Fitting

- Joints

- Flanges

- Strainer

-

Applications

- Industry

- Water and Wastwater

- Oil and Gas

- Chemical and Petrochemical

- Mining and Metal

- Food and Drinking

- Slurry and Paper

- Power

- Marines

-

Resources

PRODUCT DETAILS

Triple Offset Butterfly Valve

Specification

| Size range | Body Material |

| Flange type:2"~120"(DN50~DN3000) | Ductile Iron, Carbon Steel, Stainless Steel and Al-bronze etc. |

| Temperature range | Stem Material |

| -320°F to 842°F (-196°C to 450°C) | Stainless Steel, Monel K500 |

| Pressure ratings | Disc Material |

| Up to ASME 900Lb (PN160) | Ductile Iron, Stainless Steel and Al-bronze etc. |

| Shuttoff ratings | Seat Material |

| Bidirectional Bubble-tight | Stainless Steel overlaid or replaceable Solid Seat |

| Disc Seal | Retain Ring |

| Multi-layer stainless Steel or Solid stainless Steel | Stainelss Steel |

| Design & Manufacturing | Face to Face |

| API 609, EN593, JISB2032, GB/T12238 | API 609, EN558, JISB2002, GB/T12221 |

| End connection | Test & Inspection |

|

ASME B16.1 Class 125, ASME B16.5 Class 150, EN 1092 PN10, PN16, GB/T 17241, GB/T 9113, JIS B2220 |

MSS SP-61, API 598, EN 12266-1,JIS B2003, GB/T13927 |

Featurers and Benifits

Huanqiu's Triple offset butterfly valves are a type of industrial valve that is widely used for regulating the flow of fluids in various applications, which are designed to provide a tight seal with minimal torque, reducing the wear and tear on the valve components; and are designed to have a zero leakage rate and offer superior performance over other types of butterfly valves.

Huanqiu's Triple Offset Metal Seated Butterfly Valves are the premier isolation valves that provide outstanding performance and reliability in a wide range of applications and service conditions. Triple offset butterfly valves designed and manufactured to applicable requirements provide good sealing from vacuum to pressures of 1500 PSI (103 Bar) at temperatures from -425°F (-254°C) to +1500°F (816°C) performance.

Design

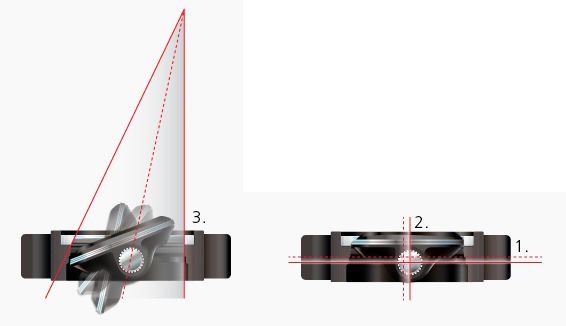

Triple Offset Geometry

The Triple offset valve or triple eccentric valve features a stem that is offset on both the X (1) and Y (2) axis of the butterfly valves center-line. This produces a cam-like motion as the valve operates. The third offset (3) consists of an inclined conical profile machined into the valve sealing surface, allowing rotary engagement and disengagement of the seat and seal ring without interference. This triple offset eliminates all rubbing between the seat and seal ring during valve travel, reducing seat and seal wear and extending cycle life.

Once the seat and seal ring are fully engaged, torque is applied in order to create a bi-directional, zero leak, metal-to-metal seal. For this reason, triple offset valves are often defined as "torque-seated" rather than "position-seated" as in the case of resilient or high-performance products.

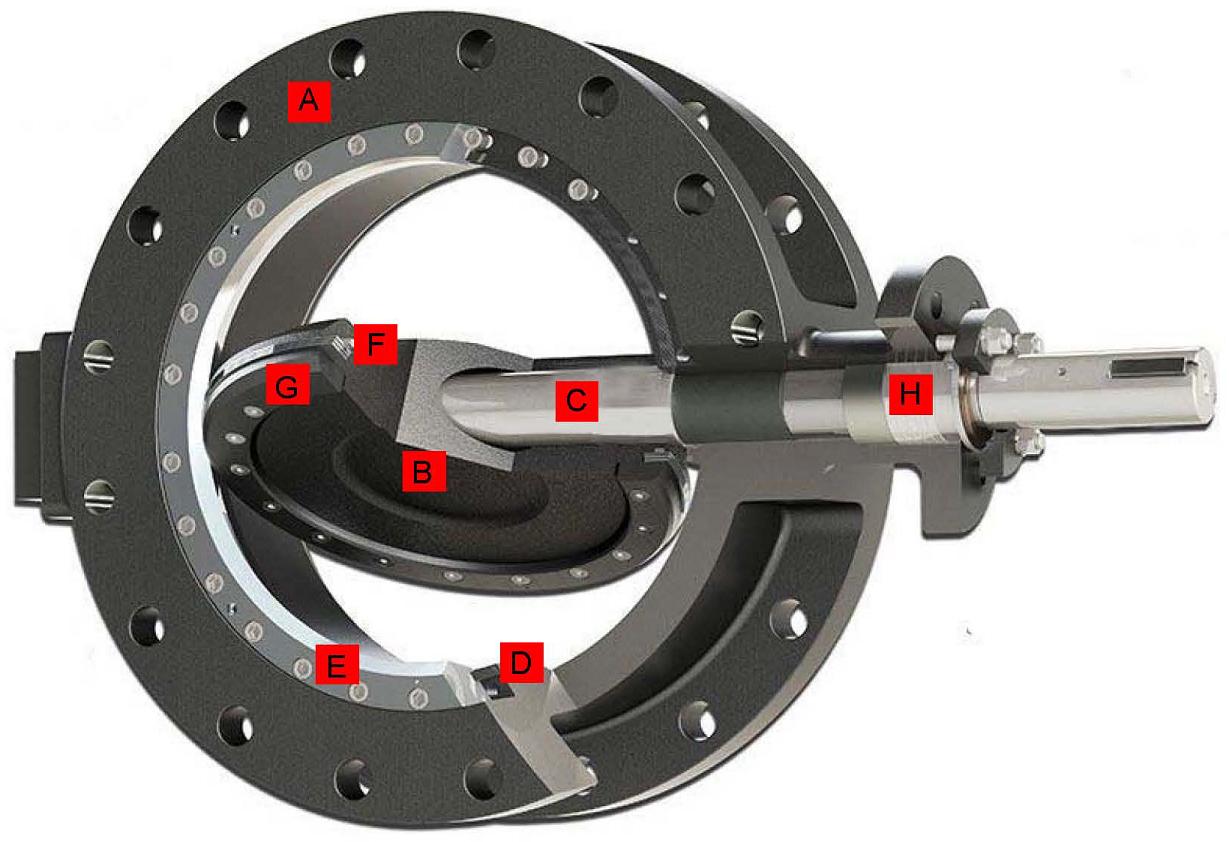

| A Body:Heavy duty body, triple offset construction. |

|

B Disc:The strong and reliable connection allows for axial movement of the stem independent of the disc, to protect the disc/stem connection from temperature fluctuations and pressure effects. |

|

C Stem: Provides positive visual indication of disc/seal ring position after installation. |

|

D Seat:The fully field-replaceable seat extends overall life, minimizes downtime, and and reduces the need for costly off-site repairs or total replacement. |

|

E Seat Retainer: Stainless Steel material to make sure the seat unmoveable. |

|

F Seal Ring:The fully field-replaceable non-rubbing, metal-to-metal sealing system is inherently firesafe and fire-tested, while meeting zero-leakage requirements for many critical applications. |

|

G Seal ring Retainer: Stainless Steel material to make sure the seal ring unmoveable. |

|

H Bushing: Hardened bearings provide maximum stem support. |

Download catalogue here

Butterfly Valve

Products